We offer many types of substrate configurations, printing processes, and bag options. Whether you need unprinted roll stock or printed stand-up pouches with additional features, we can engineer the perfect solution for you.

Our barrier film is perfect for protecting, preserving, and increasing the shelf life of your product. We measure our barrier film by its capacity to limit the admission of carbon dioxide, oxygen, and moisture. It is perfect for frozen and fresh food products, extending product shelf life, and preserving flavor.

With advanced printing and lamination technologies, we are capable of running either short or long runs. No matter what size or quantity you may need, our packaging specialists can make it work!

We offer a wide variety of packaging to cater the differing needs of our customers. We offer flexible packaging, corrugated, chipboard, labels, and much more.

At CDB Packaging, we know that, in the food industry, product safety is of the utmost importance. That is why we have invested our time and resources in acquiring SQF Food Safety Certification and AIB Certification. These certifications are what set us apart from our competitors and serve as testaments of our commitment to providing the safest product on the market!

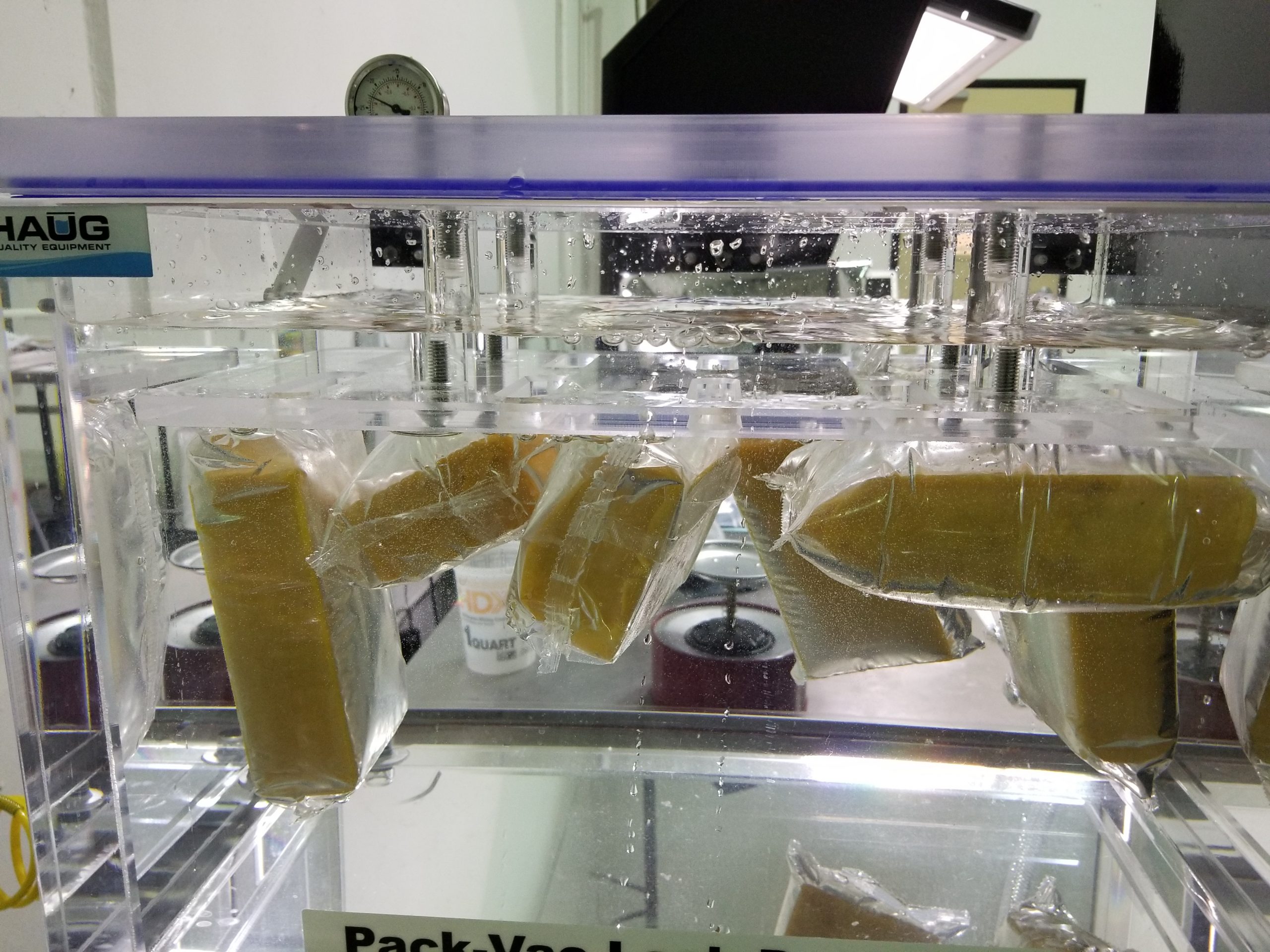

At CDB Packaging, we offer a multitude of diagnostics tests to ensure our standard of quality. We test for seal integrity using our specialized Pak-Vac Leak Detector™, which allows us to test in atmospheric conditions, simulating upwards of 20,000 ft. above sea level. We use this equipment to run a variety of ASTM test methods for detecting leaks and ensuring seal integrity. We test for accurate color on our printed packaging with our state-of-the-art Spectro Densitometer. With this equipment, we can measure, reproduce, and calibrate colors, specifically on our printed film. It is perfect for ensuring colors are both accurate and consistent throughout a run. All of our films are tested for strength and durability using our tensile tester. This instrument indicates how our film will react to forces being applied in tension. We run these tests to determine the elastic limit, elongation, proportional limit, and reductions in strength, area, yield point, yield strength, and other tensile properties. We also test for static and kinetic coefficients of friction for all our flexible packaging materials. CoF is a ratio that indicates the force required to move one surface over another surface. This measurement is vital to the performance of film when running on a form, fill and seal machine.